HFC (Water-glycol flame resistant hydraulic fluid)

HFC hydraulic fluid is a kind of flame resistant hydraulic fluid composed of 30%~55% water (distilled water or deionized water), 25%~45% ethylene glycol, propylene glycol or their polymers, water-soluble thickeners and anti-wear, anti-rust, defoaming and other additives. Water is one of the flame retardant components, and the liquid has excellent flame resistance, high viscosity index, good stability and fluidity, and is a transparent true solution.

Due to the large water content, the use temperature can not exceed 65 °C, generally used in the system of no higher than 20MPa pressure, and water-in-oil, it can use the same sealing and hose materials as mineral oil, and in the metal material except zinc, cadmium, magnesium is generally adaptable. Specially selected epoxy-based coatings are used for coatings.

Ethylene glycol liquid has a certain toxicity, but as long as it is prevented from entering the mouth, it will not cause harm to the human body. The water-ethylene glycol solution should be regularly monitored for viscosity, water content and pH changes. If the viscosity and pH value exceed the specified index, water and additives should be added. When there is too much dirt, the liquid should be drained for filtration.

HFC Advantages and Disadvantages

It is prepared with a mixture of water and ethylene glycol as the basic ingredient (according to the specific formula system, the water content varies from 40-60%), and various anti-wear, anti-oxidation, anti-foaming, anti-rust and other components are added, and the comprehensive manufacturing cost is lower than that of synthetic ester hydraulic oil. Due to the water-based system, the cooling performance, flame resistance and special chemical structure make the water-glycol hydraulic fluid have a low pour point (generally up to -45°C) and a high viscosity index, which is suitable for devices with very low operating temperatures.

However, water-based products will also have some natural defects as hydraulic media, mainly in the following aspects:

(1) the anti-wear performance of the base medium is insufficient, relying on additives to improve, but the matching of water-based products to additives is not as good as the oil-based system, so the performance is not good in inhibiting equipment wear, the system using water-based hydraulic fluid, the damage frequency of hydraulic pump and control valve is generally very high, and the cost control of oil can not make up for the loss caused by equipment damage;

(2) water-based products are difficult to solve the problem of rust prevention in the system, and the compatibility with sealing materials is not good, so the frequency of leakage in the process of use is more than that of oil products, so the common water-ethylene glycol hydraulic fluid on the market will generally be equipped with bright colors to facilitate the rapid detection of leakage points when leaking;

(3) Water volatilization – the temperature of its use is limited to no more than 60 °C, and the closed fuel tank does not exceed 55 °C, otherwise the volatilization of water will cause the viscosity of the oil to increase, affecting the use. In the process of use, due to the volatilization of water, it is necessary to replenish the oil product regularly, and the price advantage of the oil product is difficult to make up for the consumption of the amount.

HFDU (Fatty acid ester/Synthetic ester type flame retardant hydraulic fluid)

Ester flame resistant hydraulic fluids are mainly divided into phosphate ester type (HEDR) and fatty acid ester type (HFDU). HFDU hydraulic oil is based on synthetic ester oil and blended with additives with anti-oxidation, anti-corrosion and anti-wear additives, which can be used for all kinds of hydraulic system transmission media with anti-flame requirements.

Fatty acid ester flame resistant hydraulic oil has excellent lubricity, high and low temperature stability, wider service temperature range, good flame resistance, biodegradability and long service life, so it is widely used in metallurgy, building materials, electric power and other industries in contact with high temperature or open flame hydraulic system. Fatty acid ester flame retardant hydraulic fluids are more than 2 times more expensive than ordinary mineral oil type hydraulic fluids, so they are only used in applications where flame resistance and biodegradability are required.

HFDU Disadvantages and Advantages

HFDU hydraulic oil has a high viscosity index, so that it has good thermal stability, the viscosity will not change greatly when the temperature rises and decreases, the viscosity characteristics are better, and the viscosity change is less affected by the pressure to ensure that the friction surface has stable lubricity.

However, when HFDU hydraulic oil is applied, hydrolysis reaction will occur when it is in contact with water, which will increase the acid value, and the compatibility of HFDU hydraulic oil with lead and zinc metal is poor and incompatible with zinc-containing paint. Other types of synthetic flame retardant hydraulic fluids are designed for specific applications. Anhydrous polyether flame retardant hydraulic fluids have a long service life and are very environmentally friendly, silicone fluids are used in some critical situations, but these other types of synthetic flame retardant hydraulic fluids are very expensive.

Due to the natural advantages of synthetic ester base oils, they offer significant advantages as lubricating media over water-based products:

(1) Outstanding lubrication performance – the base oil itself is an ideal lubricating medium, and the matching with additives is also good, with good friction reduction, reduce wear characteristics, the hydraulic system failure rate using synthetic ester hydraulic oil is much lower than that of hydraulic stations using water-based products;

(2) Stable and long-term – due to the optimized design of the molecular structure, synthetic lubricants have more stable performance than mineral oils, can withstand higher temperatures, have a longer service life, and the oil is not volatile and has lower consumption during use.

(3) Comprehensive performance – in addition to the efficiency and stability of lubrication, the advantages of synthetic oil products in comprehensive performance are also obvious, and their rust prevention performance and corrosion performance to oil products are significantly better than water-based products.

Difference Between HFC and HFDU

While both HFC and HFDU hydraulic fluids can reduce fire risk, improve operational safety, and enhance environmental performance, there are significant differences. With a market adoption rate of 50-55%, HFC is a water-based fluid that can be used in all industries where there is a significant risk of fire. In contrast, HFDU is an anhydrous fluid designed to replace anti-wear mineral oil-based hydraulic fluids with a market adoption rate of 20-25%. (Source: Ronald Knecht from Quaker Houghton)

While the critical role of these two fluids is to prevent the corresponding financial losses caused by fire and application downtime, the choice of which one to adopt depends primarily on the specific needs of the application. For example, in applications with workers, such as die casting, the uncompromising fire resistance of HFCs is often favored. While in unmanned applications such as blast furnaces, the enhanced system reliability provided by HFDUs often drives decision-making.

While there is room to convert real-world applications from HFC to HFDU, the process is costly and requires extensive flushing and testing. Therefore, it is important to understand from the outset which hydraulic fluid makes the most sense from a safety, cost and environmental perspective to optimize the associated benefits of increased productivity, reduced downtime and enhanced work safety.

Applications of HFC Water-Glycol Hydraulic Fluid

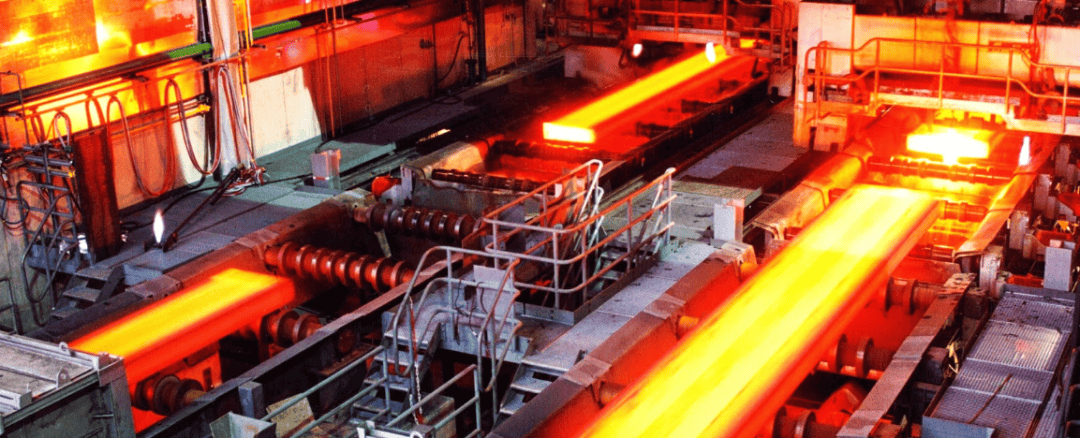

HFC (water-glycol) fluids are one of the most widely used refractory hydraulic fluids and are favored for their cost-effectiveness and combination of excellent fire resistance with good lubricating properties. HFCs are widely used in steelmaking, die casting, pressure forming, and the automotive industry, and continue to be the standard choice in the industry.

In addition to its reliable refractory properties, other reasons for choosing HFC include OEM approval and a cost similar to that of mineral oil. Unlike HFDUs, HFCs can be mixed with process water, which is important for environmental reasons.

But in the case of HFC applications, ongoing maintenance is essential, and regular sampling and analysis can prevent costly component damage. If properly maintained, HFC application systems can operate very reliably. Neglecting maintenance can lead to unplanned downtime, so downtime needs to be carefully planned to minimize inconvenience and lost revenue. With an effective maintenance plan in place, the advantages of HFC in terms of long-term cost-effectiveness and safety are clear. While the fire resistance properties of HFCs are commendable, water-based fluids can lead to shorter component life due to corrosion and cavitation if maintenance is neglected.

Application of HFDU fatty acid ester type hydraulic fluids

Despite its higher price, HFDUs are generally recognized as the best refractory alternative to mineral oils for hydraulic applications with special environmental requirements without compromising the operation and design of the entire hydraulic system.

HFDUs cost two to three times as much as mineral oil, and while the initial cost may be higher, energy consumption can be reduced by reducing overall costs due to reduced maintenance downtime and improved lubrication. In addition, HFDUs have a longer service life and can operate at higher operating pressures, thus improving the reliability of the system.

The fire resistance of HFDUs meets international standards such as Factory Mutual and is suitable for applications where there is a fire hazard, such as blast furnaces, etc., and when system reliability is critical, HFDUs are often the better choice. Since HFDUs are not miscible with water, they do not mix with wastewater, but this can lead to elevated chemical oxygen demand (COD) with other environmental and regulatory impacts. When weighing the benefits associated with water-free and water-based solutions, a holistic perspective should be considered.

Overall, HFCs and HFDUs have their advantages, with HFCs costing less but potentially presenting some challenges in terms of maintenance and environmental impact, while HFDUs offer better long-term performance and environmental benefits despite being more expensive. When choosing the right hydraulic fluid, decisions need to be made based on specific application needs, budget constraints, and environmental considerations.

China Additive of metal working oil Manufacturer and Supplier | Baoran Chemical

Post time: Apr-08-2024